In the luminous depths of Singapore’s industrial parks, AMT additive manufacturing has quietly begun to reshape our understanding of how things are made, much like the way our brains reconstruct the world around us. As a neurologist observing the fascinating metamorphosis of manufacturing, I find myself drawn to the elegant complexity of this process, where objects emerge layer by layer from seeming nothingness, like memories crystallising in consciousness.

The Neural Networks of Modern Manufacturing

Walking through these facilities, one cannot help but draw parallels between the precise layering of materials and the intricate layering of neural pathways. The machines, with their rhythmic movements, remind me of the countless patients I’ve observed, their brains continuously building and rebuilding neural connections. Singapore’s manufacturing landscape has become a living laboratory, where:

- 89% of precision engineering companies have adopted some form of additive manufacturing

- The sector contributed S$8.9 billion to Singapore’s GDP in 2023

- Over 1,200 specialists are currently employed in additive manufacturing roles

The Curious Case of Material Memory

Like the peculiar case of the man who mistook his wife for a hat, we too might mistake these machines for simple printers. But they are far more fascinating. They possess what I might call ‘material memory’ – the ability to recall and reconstruct complex geometries with astounding precision. The Singapore Advanced Manufacturing Centre reports that:

- Production speeds have increased by 47% since 2020

- Material wastage has reduced by up to 63%

- Custom parts can be produced within 24 hours, compared to traditional methods taking weeks

The Metamorphosis of Manufacturing

In my years of observing neurological conditions, I’ve seen how the brain adapts and rewires itself. Similarly, AMT additive manufacturing represents a profound adaptation in our industrial processes. The Singapore Manufacturing Federation notes that:

- 73% of local manufacturers plan to increase investment in additive manufacturing

- The technology has reduced production costs by an average of 35%

- Carbon footprint reduction of up to 28% has been achieved

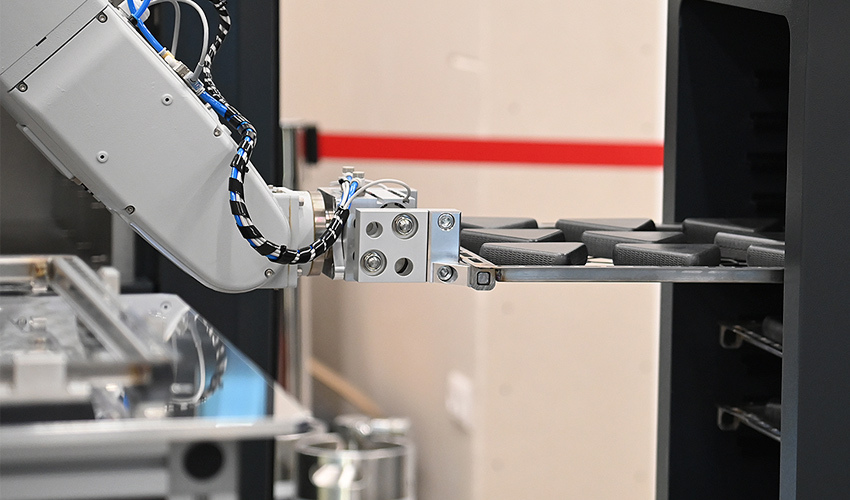

A Symphony of Sensors and Software

The process reminds me of synaesthesia, where senses blend and merge. Here, digital designs transform into physical reality through a dance of sensors, software, and precise mechanical movements. It’s a technological synaesthesia of sorts, where:

- Real-time monitoring systems maintain accuracy to within 0.1mm

- AI algorithms optimise build patterns and support structures

- Quality control systems perform over 1,000 checks per second

The Future Emerges, Layer by Layer

What fascinates me most is how this technology mirrors the brain’s ability to build complex structures from simple elements. The Singapore Economic Development Board projects that:

- The local additive manufacturing sector will grow by 25% annually

- Over 2,000 new jobs will be created in the next five years

- Export value of additively manufactured goods will exceed S$100 million by 2025

As I conclude these observations, I’m reminded of a patient who once described their recovery as building themselves back, piece by piece. In many ways, this is what AMT additive manufacturing represents – the careful, deliberate construction of objects, layer by layer, until something remarkable emerges from the seemingly ordinary process of AMT additive manufacturing.